Automated racking storage systems

Stacker cranes and warehouse management software

Innovative automation

Warehouse automation has become essential for modern companies who want to maximise speed and save time and money without compromising on safety. An investment in an automated warehouse quickly pays for itself.

The basis for an automated warehouse comes with choosing a suitable automated racking system that ensures the the advantages of automation: speed, dynamics, safety, energy and cost savings. At OHRA, we believe almost all racking systems, including shelving for small parts, can be automated, but the key factor is to determine which goods are being stored and moved (long and bulky goods are best suited for cantilever racking, whereas the pallet rack is the first choice for palleted goods).

OHRA automated storage advantages :

- Storage and equipment planning from one source

- Warehouse management software available

- Wide range of equipment types

- Both curve-going and straight-running units possible

- Up to 8,000kg load capacity

The operating mode of the storage and retrieval machine depends on the function of the warehouse. Here's a quick breakdown:

Semi-automatic warehouse

A semi-automatic warehouse uses a storage and retrieval machine for certain tasks and processes, such as order picking, and the machine will move automatically to the racking position determined by the operator. The precise positioning in front of the racking position is fully automatic, while onloading and offloading is controlled manually by the operator.

Fully automated warehouse

In a fully automated warehouse, all processes are pre-set on warehouse management software. Commands are transmitted automatically to the control unit of the storage and retrieval machine. All steps (including racking unit start-up, positioning in front of the racking position, lifting and lowering of loads, and journey to pick-up station) are fully automated, without any warehouse staff involvement.

Automated warehouse key info:

- One storage and retrieval machine to serve several aisles

- Connects to warehouse management system

- Very narrow aisle width

- Top storage level up to 20m in height, and loads of up to 5 tonnes

- Can store products up to 8m in length

Fully automated order picking warehouse

In a fully automated order picking warehouse, all storage and retrieval, picking and provision of order-related packages is fully automated. This increases the efficiency of the entire storage and order picking process, and uses available space while reducing goods damage. If a shipping order requires the picking of different individual sheets, a vacuum manipulator has the corresponding articles ready for shipping, ensuring several orders can be processed at the same time. As a result, two separate systems can put orders together very efficiently in the smallest space.

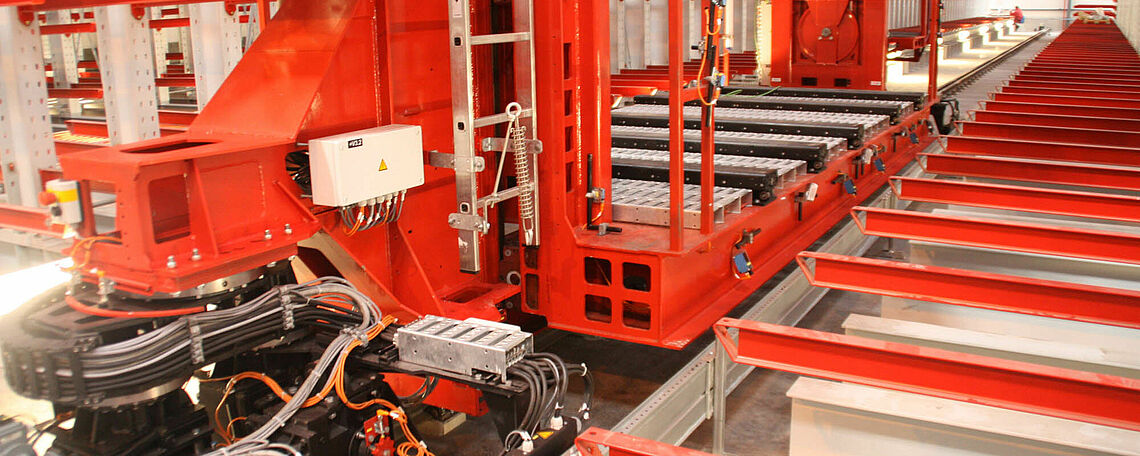

Stacker cranes

Stacker cranes are rail-guided vehicles for handling goods in an automated racking system. The maximum height of a stacker crane is 46m. Depending on the stored goods, weight and dimensions, a distinction is made between different types of stacker cranes, with three options described below:

OHRA two-mast stacker crane for long goods and heavy products

With a load-bearing capacity of up to 8 tonnes, a two-mast stacker is particularly useful when handling heavy and large-volume goods and high-rise racks are required. Often used to stack building materials, timber, slabs or in paper-processing industries a two-mast stacker can store large volumes of long goods with a relatively small footprint and for a reasonable cost.Our manual standard devices with standard platforms can be used for direct 'man at the goods' order-picking at the rack.

OHRA two-mast stacker cranes advantages

- Particularly suited for long goods

- Bearing loads of up to 8,000kg

- Device can be delivered with a platform for manual order-picking

- Curve-operation - for handling several aisles

OHRA stacker crane for up to 12m storage heights

Our special stacker crane can help you achieve automated storage of Euro pallets and pallet cages in heights of up to 12m, making it a superior alternative to VNA trucks. The crane's chassis allows for direct driving on the hall floor. The device can be curve-operated, is favourably priced and is based on a modular concept.

OHRA 12m stacker crane advantages

- Particularly suited for order-picking warehouses or automated buffer warehouses

- Modular concept

- Building height of up to 12m

- Suitable for very narrow aisle warehouses

- Curve-operation for handling several aisles

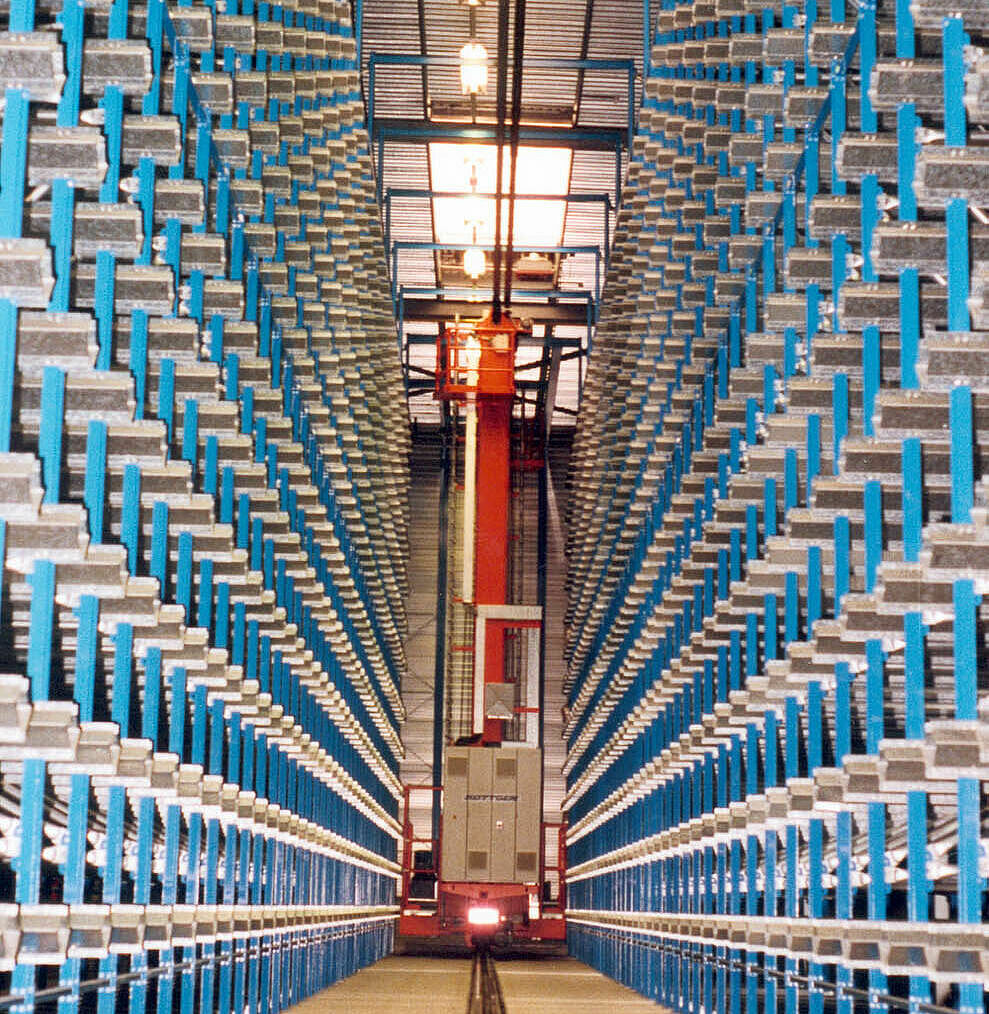

OHRA stacker crane for up to 25m storage heights

Our high-rise stacker crane is ideal for the storage of pallets and pallet caged materials in high-rise racks of up to 25m. It can come equipped with telescopic forks for single-depth or double-depth storage, or with a shuttle system or special load-carrying configuration, fully customised for your requirements. You can choose from a fully automated version or semi-automated version with a complete driver's cabin.

OHRA high-rise stacker crane advantages

- Particularly suited for high-performance warehouses

- For pallets and pallet cages with storage heights of up to 25 m

- Curve-operation for handling several aisles

TowerMat

Vertical Lift Storage System for Heavy Loads – Available in Three Versions

The TowerMat is ideal for space-saving storage of long goods, sheet metal, or pallets—especially where warehouse heights should be used efficiently. This vertical storage system is modular and flexibly adapts to both the stored goods and the building’s structural conditions. Depending on the version, cassettes or system pallets with weights of up to 8 tons can be accommodated. Goods are automatically delivered to the operator according to the “goods-to-person” principle.

Three variants are available for different storage requirements:

1. TowerMat TM-EE is suitable for small to medium storage volumes and offers a compact solution for limited floor space.

2. TowerMat TM-FE is designed for medium storage capacities and, thanks to multiple storage towers and a central stacker crane, enables particularly high efficiency.

3. TowerMat TM-RE is the most powerful version, designed for large storage volumes, featuring a side-traveling stacker crane along several storage towers.

System Features:

- Flexible design for storing long goods, sheet metal, or pallets

- Load capacity up to 8 t per storage location, total payload up to 400 t

- Machine heights up to 25 m possible

- Efficient storage and retrieval via integrated stacker crane

- Single-row or multi-row configurations available

- Optional rear operation or roof penetration

The TowerMat system can be easily integrated into existing logistics processes and increases storage capacity even in the smallest spaces.

PickMat – Automated Handling System for Laser Processing

The PickMat automates material supply for laser machines and ensures smooth processes in sheet metal processing. The system handles both the feeding of raw material and the return storage of cut sheet metal parts. Reuse of leftover sheets is easily possible. Reduced loading and unloading times lead to a significant increase in productivity throughout the manufacturing process.

Key Advantages:

- Automated connection to laser cutting systems

- Integration into existing storage systems possible

- Compatible with common manufacturers

- Short loading and unloading cycles

- Gentle and safe material handling

- Customer-specific layout

PickMat is particularly suitable for companies that want to combine high utilization in sheet metal production with automated storage technology.

InterMat – Carousel Storage System Based on the Paternoster Principle

The InterMat system is an automated carousel storage system operating on the paternoster principle. Stored goods are delivered to the operator at the push of a button—quickly, reliably, and without manual searching. Typical applications include storage of long goods, cable drums, cylinders, or rolled materials.

Technical Highlights:

- Carousel principle with access-optimized carrier control

- Especially suitable for long goods, tires, rolls, or tools

- Vertical and horizontal space utilization possible

- Special sizes and customer-specific designs available

- Ideal for pits, bridge constructions, or tight spaces

Thanks to its flexible design, the InterMat can be optimally integrated into existing production or logistics areas and makes effective use of unused overhead space.

Warehouse management software

We can design fully automated warehouse management software that develops a logistics system suited to your existing organisation structure. Based on data collected on item turnover and company structure, we can work with your employees to develop concepts to be used as a specification book for automated storage. The result is a comprehensive and optionally configurable standard warehouse management system that can achieve instant and sustainable cost savings.

OHRA warehouse management software advantages

- Real-world analysis of your existing infrastructure to improve the process quality of your warehouse and technical system

- Ensures emploxees are being deployed effectively

- Solution development

- presentation of results and specification book

- Optimisation of storage capacity

- Fifo-Lifo-BBD

- ABC classification

- Blocking of bays/stock

- Order-picking optimisation